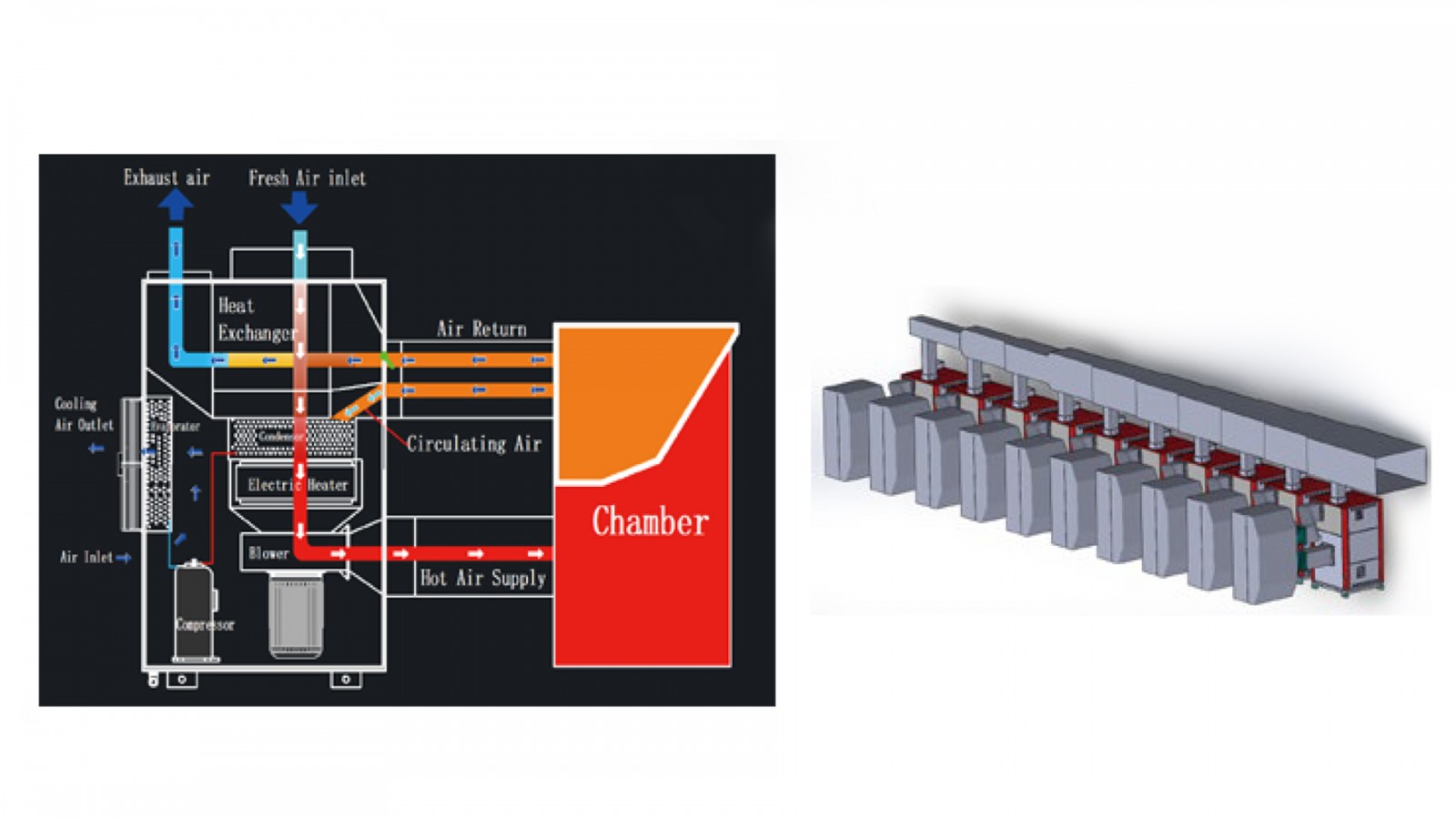

Designed for tropical areas, this dryer can greatly improve the factory working environment, stop the cooling air in winter. Its cooling capacity about 10 kW, can be widely used in rotogravure printing, compound machine, rotogravure printing machine, coating machine, laminating machine, suitable for most printing machine brand. Compared with electric heater, heat pump dryer can save 50% or more electricity.

Features:

1.Big quantity cooling air

2.80 degree got air supply

3.Intelligent control

Max 10kw large cooling air capacity powered by a big independent fan to work shop, which is equivalent to add a 6HP air conditioner.

High craft sheet metal structure, smooth and complete appearance, integrated design.

Fans inside machines to reduce noise in the work shop and under 70 dB.

Waste heat recycle to lower workshop's temp, low maintenance cost.

Short investment return cycle.