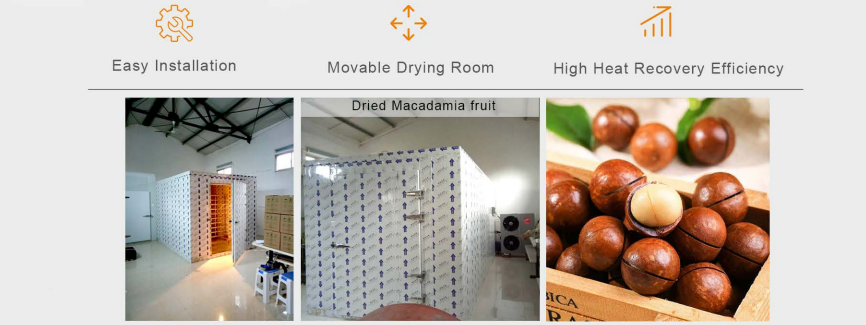

Phnix have many models for fruit and vegetable drying, which can be widely applied for most material drying.

The heat pump system can take place of traditional coal or electricity drying, energy saving ratio can be 50% or more.

Phnix have many models for fruit and vegetable drying, which can be widely applied for most material drying.

The heat pump system can take place of traditional coal or electricity drying, energy saving ratio can be 50% or more.

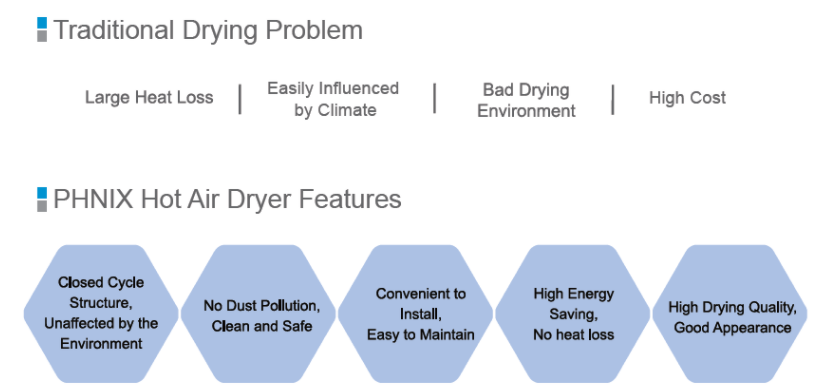

1) Energy saving and environmental protection:by using heat pump system, this dryer is more energy saving than electric heater or boiler, more environmental friendly than coal or wood burning

2)All-in-one integral design, flexible installation: Phnix fruit and vegetable dryer has many different model, can be applied to various drying condition

3)Precise moisture and temperature control, stable air supply temperature: adjust moisture and temperature freely according to different drying stages, air supply between 30~75 degree

4)Convenient operation, no need special maintenance:touch screen, visible air volume and temperature,no need human supervise

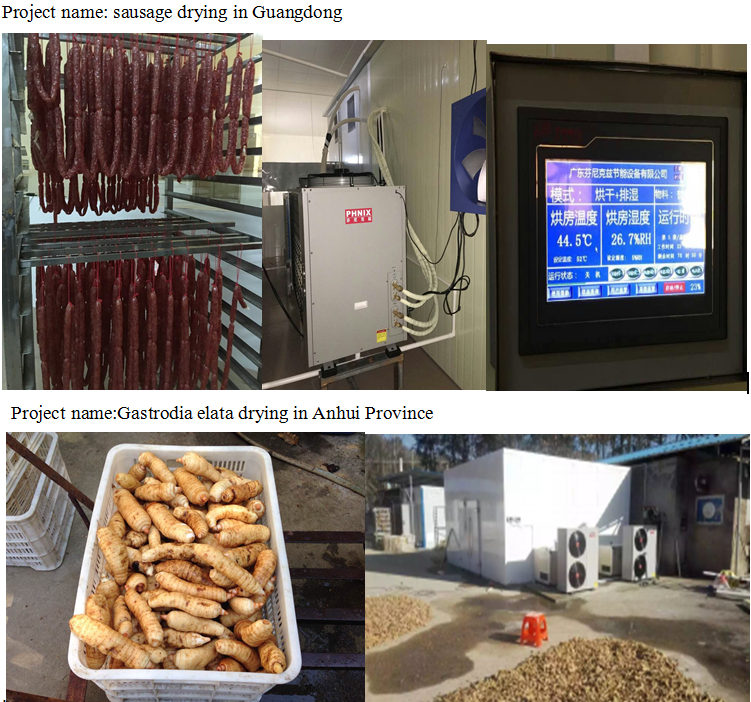

1). Drying material: traditional Chinese medicine

Location: Xihe, Gansu

Project time: December 2020

Equipment selection: 4 sets 15p integral dryers

Unit matching: 6 tons of Pinellia ternate per day, electricity consumption 60kW/h

Grape drying in Xinjiang

2).Project Name: hot pepper drying project in Pu'an County

Project time: September 2018

Equipment selection: one 50p integral heat pump dryer, daily processing capacity is 10 tons,

Energy consumption : 35kw / h.

3).Project Name: Tremella dry

Project time: March 2016

Euipment selection: 12p inte

Energy consumption : 9kw/h

4). Project Name: chrysanthemum drying in Jiangxi

Project time: August 2016

Equipment selection: 12p integral dryer * 30 sets

Unit matching: 30 sets Phnix air energy heat pumps are used. According to the field measurement, each heat pump consumes 8.5kw per hour

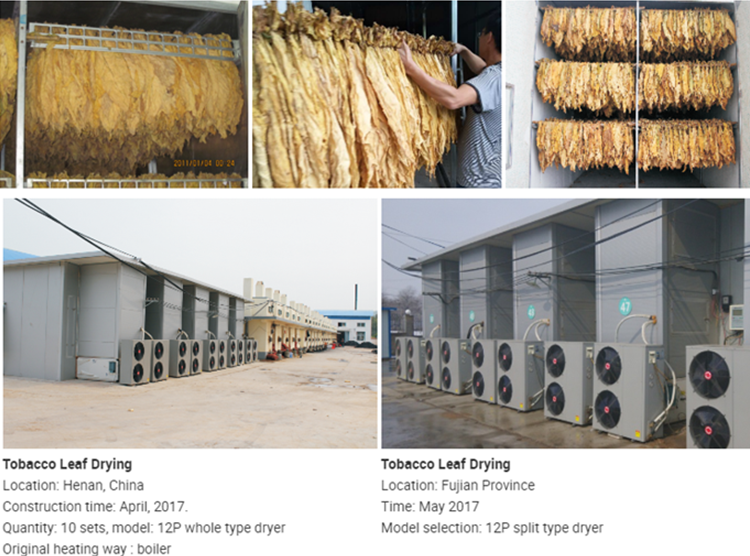

5)Project Name: Tobacco drying

6)Project Name: paper tube drying project in Guangdon

Poject time: July 20, 2019

Euipment selection: 4 sets 12p PHNIX split dryer

Unit matching: 2 drying rooms are 8.0 * 5.0 * 4.0, each unit generates 36kw heat per hour, with an average energy consumption of 12 degrees of electricity

7.Grape drying in Xinjiang

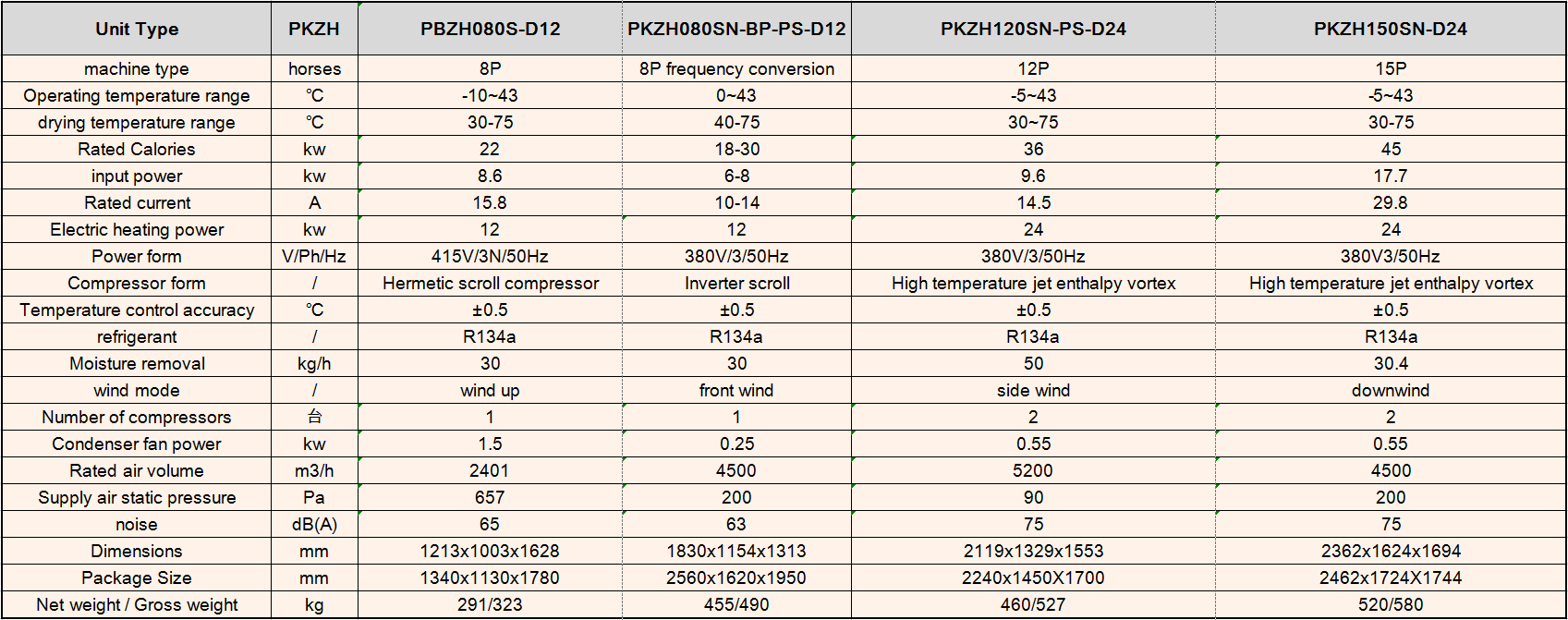

Parameters:

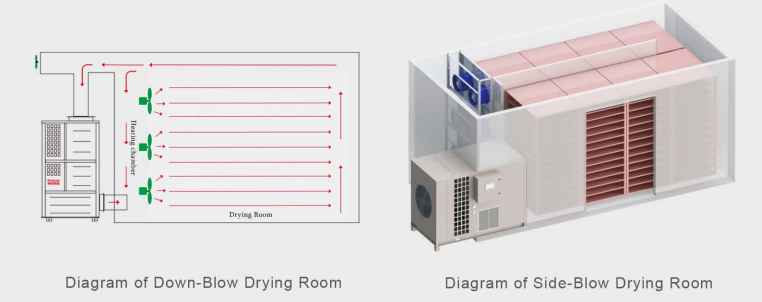

●Standard test conditions: ambient temperature 20°C, wet bulb temperature 15°C; oven temperature 60°C, relative humidity 10%;

●The moisture removal amount is calibrated under standard test conditions, and it will vary due to changes in indoor and outdoor wet bulb temperatures;

●The model, parameters and performance will be changed due to the improvement of the product, and there will be no further notice. The specific parameters are subject to the product nameplate.