PHNIX Waste Heat Low-Temp Belt technology uses flue gas, steam, and natural gas as heat sources. It features low energy use, high efficiency, and can dry sludge from 60%-82% moisture to 10%-60%. It saves over 50% energy, reduces volume by 80%, and leads in green drying.

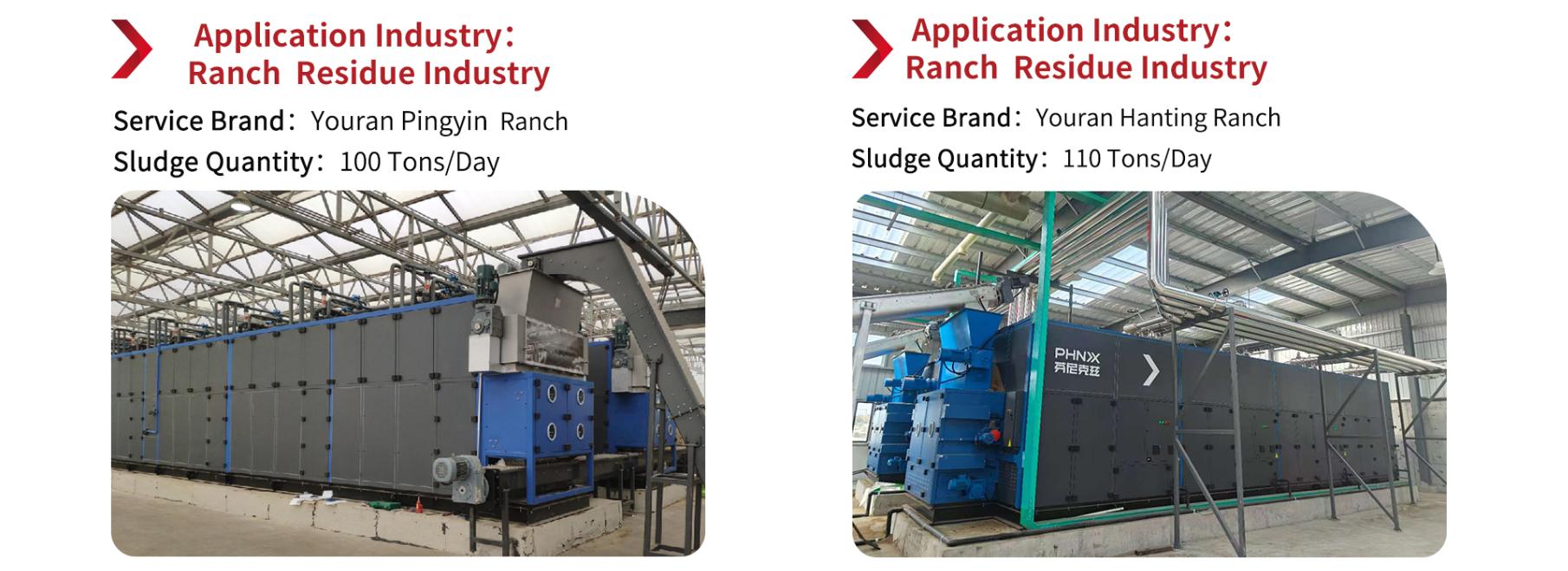

PHNIX Waste Heat Low-Temperature Belt Drying technology is widely used in drying projects of materials from the fields of municipal and industrial sludge (such as printing and dyeing, papermaking, electroplating, chemical, leather, pharmaceutical, etc.) as well as livestock digestate.

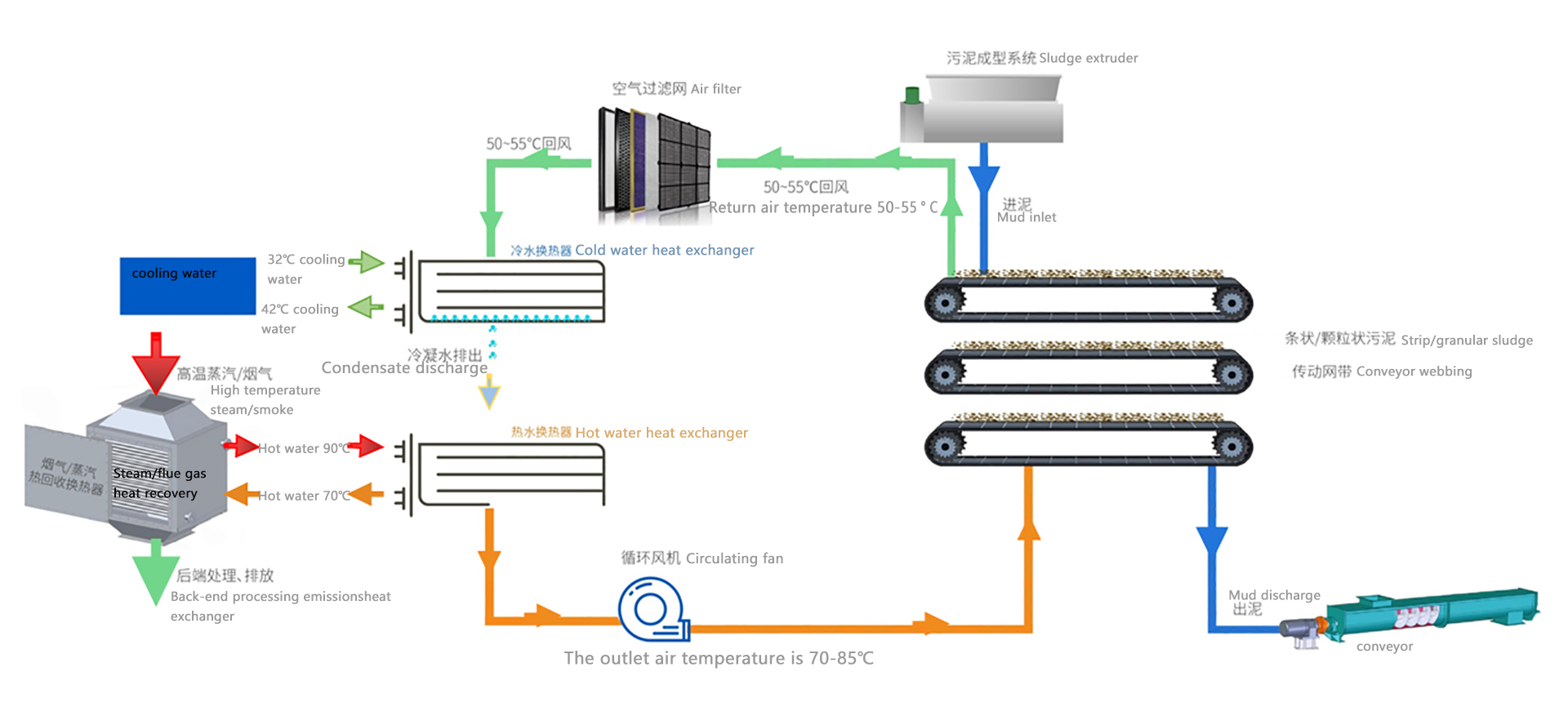

· Closed-loop drying with waste heat recovery and no waste heat emission.

· High-efficiency dewatering, with a maximum dewatering rate of 80%, and adjustable final moisture content ranging from 10% to 50%.

· Reduction of moisture content in wet materials from 80% to 30%, with dewatering energy consumption of 320 kWh/ton.

· Low drying temperature (≤85℃) and fully enclosed system, ensuring no odor emissions.

· Fully automatic operation, supporting remote centralized control and intelligent operation.

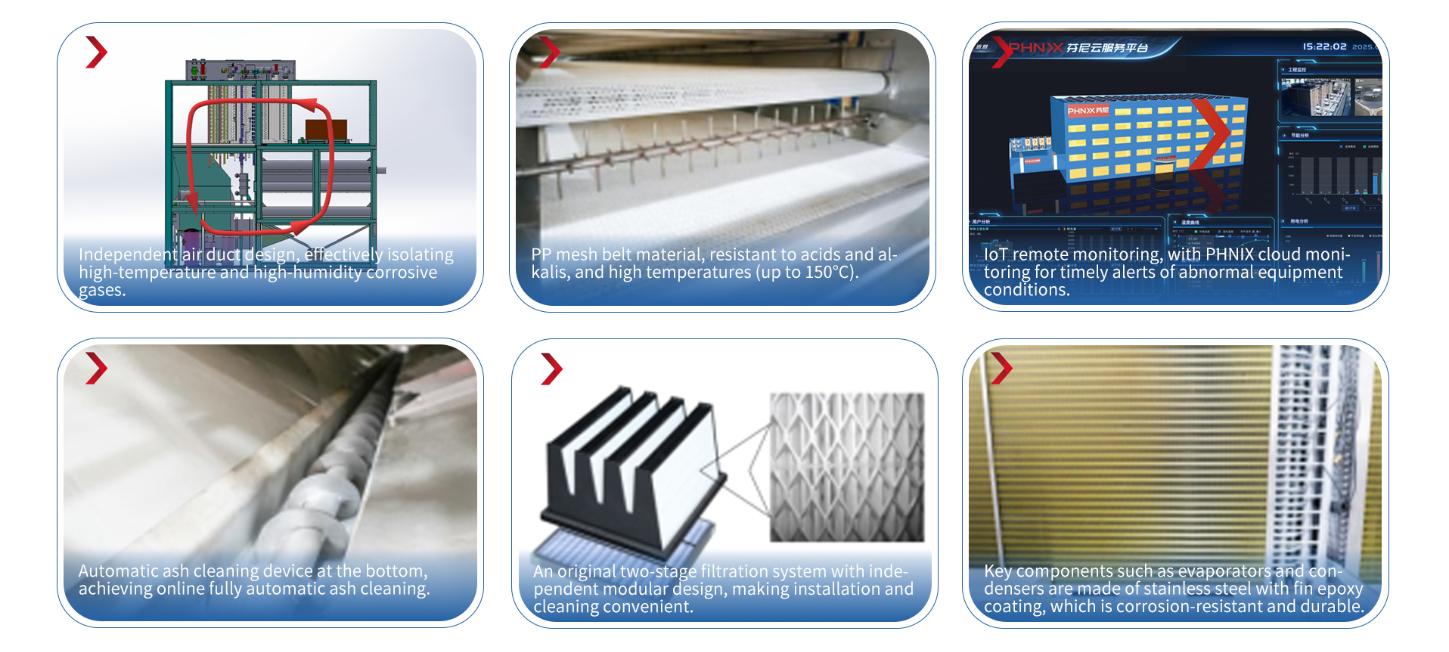

· Independent air duct design, effectively isolating high-temperature and high-humidity corrosive gases.

· PP mesh belt material, resistant to acids and alkalis, and high temperatures (up to 150°C).

· Key components such as evaporators and condensers are made of stainless steel with fin epoxy coating, which is corrosion-resistant and durable.

· Automatic ash cleaning device at the bottom, achieving online fully automatic ash cleaning.

· An original two-stage filtration system with independent modular design, making installation and cleaning convenient.

· IoT remote monitoring, with PHNIX cloud monitoring for timely alerts of abnormal equipment conditions.